CAST IRON & ITS TYPES

Ore-ore is the source of the metals .it is present in the earth crust and nature ,different types ore for different metal and non metals .ore is the mineral which metal can be extracting different types of process .blast furnace is the most iron extracting process.

or the matter which can derived from the earth crust is known as ore.

definition-Cast iron is made from pig iron, which is the product of melting iron ore in a blast furnace. Cast iron can be made directly from the molten pig iron or by re-melting pig iron,[4] often along with substantial quantities of iron, steel, limestone, carbon (coke) and taking various steps to remove undesirable contaminants. Phosphorus and sulfur may be burnt out of the molten iron, but this also burns out the carbon, which must be replaced. Depending on the application, carbon and silicon content are adjusted to the desired levels, which may be anywhere from 2–3.5% and 1–3%, respectively. If desired, other elements are then added to the melt before the final form is produced by casting

TYPES OF CAST IRON

1.GREY CAST IRON:-Gray cast iron is ordinary commercial iron having 3-4% of carbon .the gray cast iron is color gray due to the fact that carbon is present in the foam free graphite .it has good compressive strength but less tensile strength and no ductility .it can be easy machining .it has low melting point and fluidity.

👉GRAY CAST IRON SOME POINT

- Gray cast iron bassically is an alloy of carbon and silicon with iron .

- it is readily cast into a desired shape in a sand mould.

- when fractured, a bar of gray cast iron gives gray apperance.

- Gray cast iron possesses high fluidity and hence it can be cast be cast into compex shape and thin section.

- It machinability better then steel.

- It possesses high vibration damping capacity.

- Gray cast iron has a low ductility and low impact strength as compared with steel.

- Gray cast iron has as solidification rang of 2400-2000 'F.

- It has shrinkage of 1/8 inch /foot (1mm/100mm

APPLICATION /USES GRAY CAST IRON

- Machine tool structures (bed,frame)

- Gas or water pipes for underground purposes.

- Cylinder blocks and heads for I.C engines.

- Tunnel segment .

- Frames for electric motors.

- Piston rings.

- Rolling mill and general machinery parts.

- Household application.

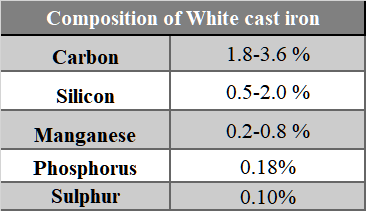

2.WHITE CAST IRON (MOTTLED IRON) :-It particular verity of cast iron having 1.75 to 2.3% carbon the white color is due to the fact that the carbon in the form of carbide .which is the hardness constituent of iron. the white iron high tensile strength and low compressive strength.

-Carbide is the alloy of iron and carbon, the carbon percentage is 6.67%. it is also known as cementite.

-Thus, white iron possesses excellent abrasive wear resistance.

-White cast iron made in sand mould.

-The white cast iron solidification rang 2550-2065°F.

-Shrinkage is 1/8 inch per foot (1mm/100mm).

Application of white cast iron

a).For producing malleable iron casting.

b).Wearing plate.

c).Rolls for crusher.

d).Rim of car wheels.

e).Railway track.

3.MALLEABLE CAST IRON -

Malleable cast iron is a form of cast iron that has undergone a special heat treatment process called annealing, resulting in a material with improved malleability and ductility compared to standard cast iron. This treatment involves the formation of irregularly shaped nodules of free graphite within the iron matrix, enhancing its ability to deform without breaking.

Composition

The composition of malleable cast iron typically includes iron as the primary element, along with a significant amount of carbon. Additionally, small amounts of other alloying elements, such as silicon and manganese, may be present. The key to malleability lies in the controlled heat treatment process that allows the formation of graphite nodules within the iron structure.

1. Pipe Fittings: Malleable cast iron is commonly used for manufacturing pipe fittings due to its combination of strength and malleability. These fittings are used in various plumbing and industrial applications.

2. Automotive Components: Certain automotive components, especially those requiring a combination of strength and the ability to absorb shock, may be made from malleable cast iron. Examples include suspension parts and some engine components.

3. Construction Hardware: Malleable cast iron finds use in the production of construction hardware such as brackets, hinges, and supports. Its malleable nature allows for the shaping of these components to suit specific design requirements.

4. Railroad Components: Some components used in the railway industry, such as couplings and brake components, are made from malleable cast iron due to its favourable combination of mechanical properties.

5. General Engineering Applications: In various engineering applications where a balance of strength, toughness, and formability is required, malleable cast iron can be employed for producing components like gears, levers, and other machinery parts.

Malleable cast iron provides a cost-effective solution in situations where the benefits of cast iron, such as good casting properties and wear resistance, need to be combined with improved malleability for specific applications.

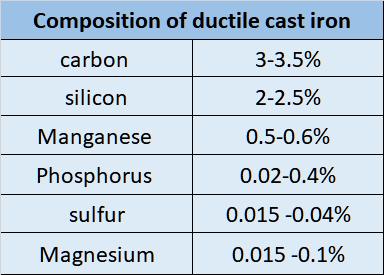

4.S.G.I{Spheroidal,Nydular,ductile cast iron} Ductile cast iron, also known as nodular or spheroidal graphite iron, is a type of cast iron that exhibits improved ductility and toughness compared to traditional gray iron. The primary characteristic that sets ductile cast iron apart is the presence of spherical graphite nodules within its microstructure, as opposed to the flake graphite found in gray iron.

The ductility of ductile cast iron is a result of the nodular shape of graphite, which allows for greater flexibility and deformation before fracture. This makes ductile cast iron more resilient and less brittle than gray iron, making it suitable for applications where strength, toughness, and resistance to shock loading are essential.

Composition

Application/UsesDuctile cast iron finds a wide range of applications across various industries due to its combination of strength, ductility, and castability. Some common applications include:

Pipes and Fittings: Ductile cast iron is widely used for the manufacturing of pipes and fittings in water and wastewater systems. Its corrosion resistance and durability make it suitable for underground and above-ground installations.

Automotive Components: Ductile cast iron is employed in the automotive industry for manufacturing parts such as crankshafts, camshafts, pistons, and differential housings. Its high strength and impact resistance contribute to the longevity and reliability of these components.

Machinery and Equipment Parts: The material is used to produce a variety of machinery and equipment parts, including gears, pulleys, brackets, and housings. Its mechanical properties make it suitable for applications that require strength, wear resistance, and durability.

Construction and Infrastructure: Ductile cast iron is utilized in the construction industry for items like manhole covers, frames, and grates. Its ability to withstand heavy loads and resist corrosion makes it a reliable choice for infrastructure components.

Railway Components: Ductile iron is used for manufacturing railway components such as brake systems, couplings, and railcar parts due to its excellent strength and wear resistance.

Valves and Pumps: The material is commonly employed in the production of valves and pump components for various industries. Its good machinability and resistance to wear make it suitable for applications involving fluid control and transportation.

Agricultural Machinery: Ductile cast iron is used in the manufacturing of agricultural equipment and machinery components, providing strength and durability for applications in harsh agricultural environments.

Wind Turbine Components: Certain components of wind turbines, such as hubs and structural supports, may be made from ductile cast iron due to its strength and ability to withstand dynamic loads.

Marine Applications: In marine environments, ductile cast iron is used for components like propellers, pump casings, and ship engine parts due to its corrosion resistance and mechanical properties.

Energy Industry: Ductile cast iron may be utilized in various energy-related applications, including components in power generation plants, such as pipes, fittings, and structural elements.

0 Comments

have a any doubt write comment section